LED Interior and Exterior Lighting

HT Lighting Limited LED lighting products are sophisticated opto-electronic devices designed for durable, energy efficient, maintenance free operation. Recent quantum leaps in the luminous intensity of LEDs per watt have allowed marine lighting systems to develop significantly to effectively illuminate a vessel's interior.

To take advantage of the ever increasing efficacy of the most advanced LEDs, efficient optic design is essential to capture and spread the available luminous flux emitted by the LED and to evenly illuminate areas. With significant advances of LED brightness, eye safety considerations are increasingly important. It is essential for high power LEDs to be coupled with optic designs that protect the eye's retina from possible damage when viewed directly. It is desirable for the entire lens area of a lamp to be evenly illuminated via an efficient optic rather than using a multiple of LEDs without any optic. Easily visible LEDs inside a luminaire without any optic or lens protection can cause a degree or even significant eye discomfort if viewed directly.

Quality LED lighting provides many significant advantages over traditional filament based sources. Significantly reduced power consumption, increased reliability, reduction in radiated heat and attractive ambient effects are all benefits of modern LED lighting systems. The following are key considerations when selecting LED lighting for marine interior and exterior applications.

Power saving on board

The single most influential driver for LED technology on most yachts and powerboats is the considerable power saving on offer compared to incandescent lamps. Lighting systems are a major part of a vessel¡¯s electrical architecture where consumption can be dramatically reduced. The opportunity to save hundreds of amp hours is available now.

As a recent example, the entire HT Lighting Limited LED lighting system specified for a Maritimo 73ft motor yacht draws less than 7 Amps. To illuminate the same interior layout with halogen lamps would have totalled over 62 Amps. The reduction in cable size and weight together with the safety aspects of an almost zero heat signature was also highly beneficial.

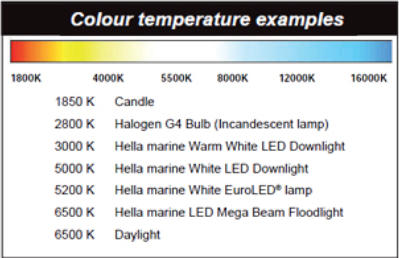

The majority of the lamps specified for the Maritimo 73 system are the compact 'Rakino' series LED downlights. Each lamp consumes less than 0.8W yet produces the equivalent light output of a 10W halogen lamp. Such efficiency is class leading.

HT Lighting Limited

Due to their solid state nature, LEDs do not have filaments to break, however LEDs do require precise current regulation and voltage protection to provide long term reliability. For LED lighting manufacturers, many design and engineering milestones are required to produce durable products that provide ongoing performance in marine applications. HT Lighting Limited LED products feature several key advantages such as completely sealed housings, sealed cable entries, effective electronic protection, shock, vibration and impact resistant components that all contribute towards outstanding reliability. Compared to incandescent lighting, where a filament inside a bulb may break at any moment, Hella marine LED lighting is ¡®fit and forget¡¯.

Many LED lamp manufacturers claim operating lifetimes of 50,000 or 100,000 hours, however in many cases these claims are generalized. The high power LED devices are often too new to have been thoroughly tested for such periods. These lifetime estimates are often based on LED component specifications from the device manufacturer rather than the life of the complete lamp in a marine installation.

In the harsh marine environment, salt air corrosion to circuit boards, light degradation due to excessive heat, vibration fatigue, shock loads, voltage fluctuations and low battery voltages all contribute to reduce the operating life of LED lamps without thorough engineering and electronic protection. The supplier¡¯s warranty policy, integrity and track record is often a more accurate benchmark on the lifetime and quality of the LED lamp under consideration.

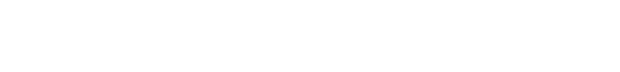

Colour Temperature and Rendering

Until recently, the lack of high quality white LED devices with sufficient intensity has een the major factor preventing the acceptance of LEDs for general marine lighting purposes.

LEDs had a reputation for appearing ¡®cold¡¯ and ¡®blue¡¯ due to there phosphorous coating heritage. However today¡¯s high efficacy devices can rival traditional incandescent light sources for colour and ambience.

When selecting LED interior lighting, colour temperature is an important consideration.

Colour temperature is measured in Kelvin and describes the effect of heating an object until it glows incandescently. The emitted radiation, and apparent colour changes in proportion to the temperature; envisioned when considering hot metal in a forge that glows red, then orange, and then white as the temperature increases.

HT Lighting Limited describes higher colour temperatures (>5200K or more) as ¡®cool¡¯ white, and lower colour temperatures (K range) as ¡®warm white¡¯. ¡®Neutral white¡¯ is in 4200K range. Cool white is recommended for visual tasks, work areas such as engine rooms, and exterior lighting. Warm white light is suggested for interior spaces as it adds life and vibrancy to people and objects, is considered more flattering to skin tones or fabrics, and makes food look fresh and attractive.

These colour choices should only be an approximate consideration however. Cool white will accentuate blue and green hues in certain fabrics and surfaces, and where there are stainless steel or gel coat surfaces.

Lighting designers may specify cool white for galley areas and warm white where there is an abundance of varnished timber work instead of high gloss gel coat surfaces.

Light Output

For an effective comparison of the different products from marine LED manufacturers, many factors must be considered. The best lamp for a given application is no longer the one that solely meets a style requirement. Today, power consumption, efficiency, output and beam angle must be considered together with light colour, shape, and the aesthetics and finish of the housing itself.

The following performance data is worth considering -

Luminous Flux

Measured in Lumens (lm), luminous flux describes the total quantity of light produced from a lamp. The higher the lumen count, the more intense the light output.

Luminous intensity

Measured in Candela (cd), luminous intensity is the luminous flux at a particular angle from the light source. Peak candela occurs at 0 degrees, i.e. directly below a lamp.

Illuminance

Measured in Lux (lx), Illuminance is equal to luminous flux divided by the illuminated area. One lux is equal to one lumen per square meter.

Luminous Flux (Lumens) / Area = Illuminance (Lux) or Illuminance (Lux) x Area = Luminous Flux (Lumens)

If both the area to be illuminated and the desired level of illumination are known, the total number of lumens required can be calculated. Divide the total lumens by the output of the LED lamp under consideration to determine the number of fixtures required to deliver the desired light output.

Eg, A powerboat salon of 10 square meters and the desired illumination level is 120 Lux, a total of 1200 lumens are required. If the LED lamp under consideration has a luminous flux of 80 lumens, 15 lamps will be required (1200 / 80 = 15).

For further comparisons it is also important to consider the beam angle of an LED lamp, and the lux levels available at varying distances from the device. Narrow light beams may provide effective intensity directly under the fitting, but may not evenly illuminate an interior as the light may be too narrow with many shadows between effectively lit areas.

Efficacy

Like efficiency, the efficacy of an LED lamp is the amount of light it produces per unit of electrical power it consumes (lumens per watt).

The higher the lumens per watt, the higher the efficiency.

E.g. A single Hella marine 9599 series white LED downlight consumes less than 0.8W and produces around 80 lumens. 80 / 0.8 = 100 lumens per watt.

It may also be an interesting comparison to divide the luminous flux of a lamp by its cost to derive lumens per dollar. The more lumens per dollar (flux per bucks), the more light for your investment.

Also, it is important to determine that the efficacy of the LED lamp is measured as the devices total efficacy, not the efficacy of only the LED(s) employed. Power consumed to run an electronic power supply driving and controlling the LED(s) is always a contributor to the lamps total consumption.

Heat reduction and thermal management

With the power saving benefits of efficient LED based devices also comes heat reduction benefits. The sometimes dangerously high temperatures of 10W and 20W halogen lamps onboard can be eliminated with high efficiency LED technology. This allows boat builders and designers a wide scope of installation possibilities where the air cavity behind incandescent lamps, traditionally reserved for cooling, is no longer required. Efficient LED lamps can be mounted into solid surfaces and composite structures without risk of fire or heat damage to surrounding materials.

Well engineered thermal management of an LED device is essential for long-term durability. A common misconception is that LED¡¯s do not generate heat. LEDs consume power and some of this power is also converted into heat, even in the most energy efficient LEDs. In contrast to incandescent lamps however LED¡¯s like to ¡®run cold¡¯. As a rule of thumb, the hotter an LED runs the faster it will degrade. A lower, and in extreme cases much lower light performance will result.

High performance LED¡¯s do generate heat, which needs to be coupled to surfaces designed to efficiently transport the heat away from the LED itself. LEDs that overheat, meaning the junction temperature of the LED rises above a set threshold, will permanently degrade and significantly reduce their luminous efficacy.

A noticeably ¡®hot to touch¡¯ exterior surface of a high output LED interior lamp provides some indication that the light output of the device will deteriorate within a few hundred hours. HT Lighting Limited LED lamps will operate ¡®cool¡¯ or ¡®slightly warm¡¯ to the touch after many hours of operation.

HT Lighting Limited thermal management expertise, coupled with proven optics and electronic design, ensures the long term durability with minimal degradation over many years of service.

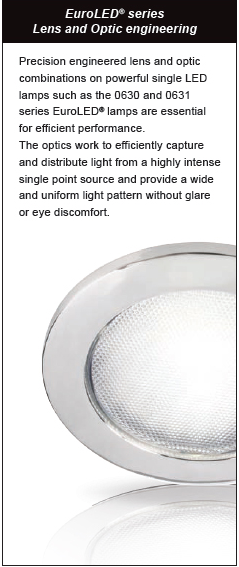

Lens and Optic Technology

To maximise the ever increasing efficacy of advanced LEDs, efficient optic design is essential to capture and spread the available light and to evenly illuminate areas on board.

Unlike incandescent light sources, LED devices begin with a directional light pattern. The goal for optics designers, working an application such as interior down lighting, is to create optics and lens patterns that produce an effective spread of homogeneous illumination throughout the interior. This even spread of light is often more important than how intense a lamp looks when viewed straight on.

All HT Lighting Limited LED lamps use efficient optics, lens designs or Free-Form reflector technology to accurately capture and distribute large percentages of available light from the LED source or sources.

Examples include:

- Oblong LED step lamps with a 30 degree down angle light beam to illuminate the tread of steps and stairs without dazzle from the lamps themselves.

- Round and Square LED courtesy lamps providing attractive uniform light patterns via an efficient optic and lens with embedded glass spheres for minimum light losses.

- EuroLED lamps employ an finely machined optic and lens combination to provide an even spread of bright white light with minimum light losses.

- 9599 series LED downlights with powerful ¡®Spot¡¯ or ¡®Spread¡¯ light distribution patterns without glare.

Lens, Optic Technology and Eye Safety

To take advantage of the ever increasing efficacy of the most advanced LEDs, efficient optic design is essential to capture and spread the available luminous flux emitted by the LED and to evenly illuminate areas.

With significant advances of LED brightness, eye safety considerations are increasingly important.

It is essential for high power LEDs to be coupled with optic designs that protect the eye¡¯s retina from possible damage when viewed directly.

It is desirable for the entire lens area of a lamp to be evenly illuminated via an efficient optic rather than using a multiple of LEDs without any optic. Easily visible LEDs inside a luminaire without any optic or lens protection can cause a degree or even significant eye discomfort if viewed directly.

Costs

Quality LED interior and exterior lamps have shifted lighting systems from an incandescent globe based inside a housing or reflector to complex engineered opto-electronic devices. These devices now incorporate advanced drive circuits, spike and over voltage protection, optics, lenses, plus the LED source itself.

As a result, the added features and benefits of effective LED lighting do carry higher costs compared to incandescent lamps. However, for many applications the substantial power savings, long term reliability and improved safety advantages are a convincing value proposition for astute owners and operators.